Quality Inspection For Ringlock Scaffolding System - Octagonlock Scaffolding System – Huayou

Quality Inspection For Ringlock Scaffolding System - Octagonlock Scaffolding System – Huayou Detail:

Octagonlock System is one of disclock scaffolding , it seems like ringlock scaffolding , European allround scaffolding system, they have many samilarities. But cause the disc welded on standard like a octagon that we call it as octagonlock scaffolding. We can produce all components and sizes of octagonlock scaffolding system, including different surface finishing like painted, powder coated, electro-galvanized and hot dipped galvanized, of them the hot dipped galvanized is the best quality that is most durable and corrosion-resistant.

Octagonlock standard

Octagonlock Scaffolding is also a modular scaffolding system. The standard is the vertical part of the whole scaffolding system, and called octagonlock standard or octagonlock vertical. It is welded octagon ring at 500mm intervals. The thickness of Octagon ring is 10mm with Q235 steel material. The Octagonlock standard is made by scaffolding pipe OD48.3mm and thickness 3.25mm, and the material usually are Q355 steel which is high quality steel so that octagonlock standard has a higher load capacity.

As we know, ringlock scaffolding usually use inserted joint pin to connected between the ringlock standards, and only a few use sleeve spigot. But for octagonlock standard we can see it is nearly all standards welded a sleeve spigot at one end.

The specification of octangonlock standard as below

|

No. |

Item |

Size(mm) |

Length(mm) |

Materials |

|

1 |

Octagonlock Standard 0.5m |

48.3*3.2 |

500 |

Q355 |

|

2 |

Octagonlock Standard1.0m |

48.3*3.2 |

1000 |

Q355 |

|

3 |

Octagonlock Standard 1.5m |

48.3*3.2 |

1500 |

Q355 |

|

4 |

Octagonlock Standard 2.0m |

48.3*3.2 |

2000 |

Q355 |

|

5 |

Octagonlock Standard 2.5m |

48.3*3.2 |

2500 |

Q355 |

|

6 |

Octagonlock Standard 3.0m |

48.3*3.2 |

3000 |

Q355 |

Octagonlock ledger

Octagonlock Ledger is most like ringlock ledger compare with standard. It also usually made by steel pipe OD48.3mm, and thickness are 2.5mm that can save cost for our clients but we can do different thickness for customers’ different requirements . Certainly, the thicker the quality will be better. Then Ledger will be welded with ledger head or called ledger end by two sides. And the length of ledger is the distance of the center to center of two standards which the ledger connected.

|

No. |

Item |

Size(mm) |

Length(mm) |

Materials |

|

1 |

Octagonlock Ledger 0.6m |

48.3*2.5 |

600 |

Q235 |

|

2 |

Octagonlock Ledger 0.9m |

48.3*2.5 |

900 |

Q235 |

|

3 |

Octagonlock Ledger 1.2m |

48.3*2.5 |

1200 |

Q235 |

|

4 |

Octagonlock Ledger 1.5m |

48.3*2.5 |

1500 |

Q235 |

|

5 |

Octagonlock Ledger 1.8m |

48.3*2.5 |

1800 |

Q235 |

|

6 |

Octagonlock Ledger 2.0m |

48.3*2.5 |

2000 |

Q235 |

Octagonlock diagonal brace

Octagonlock diagonal brace is the scaffolding pipe riveted with diagonal brace head on two sides and it is connected with standard and ledger, that can make the octagonlock scaffolding system to be more stable. The length of diagonal brace will depends on the standard and the ledger which it is connected.

|

No. |

Item |

Size(mm) |

W(mm) |

H(mm) |

|

1 |

Octagonlock Diagonal Brace |

33.5*2.3*1606mm |

600 |

1500 |

|

2 |

Octagonlock Diagonal Brace |

33.5*2.3*1710mm |

900 |

1500 |

|

3 |

Octagonlock Diagonal Brace |

33.5*2.3*1859mm |

1200 |

1500 |

|

4 |

Octagonlock Diagonal Brace |

33.5*2.3*2042mm |

1500 |

1500 |

|

5 |

Octagonlock Diagonal Brace |

33.5*2.3*2251mm |

1800 |

1500 |

|

6 |

Octagonlock Diagonal Brace |

33.5*2.3*2411mm |

2000 |

1500 |

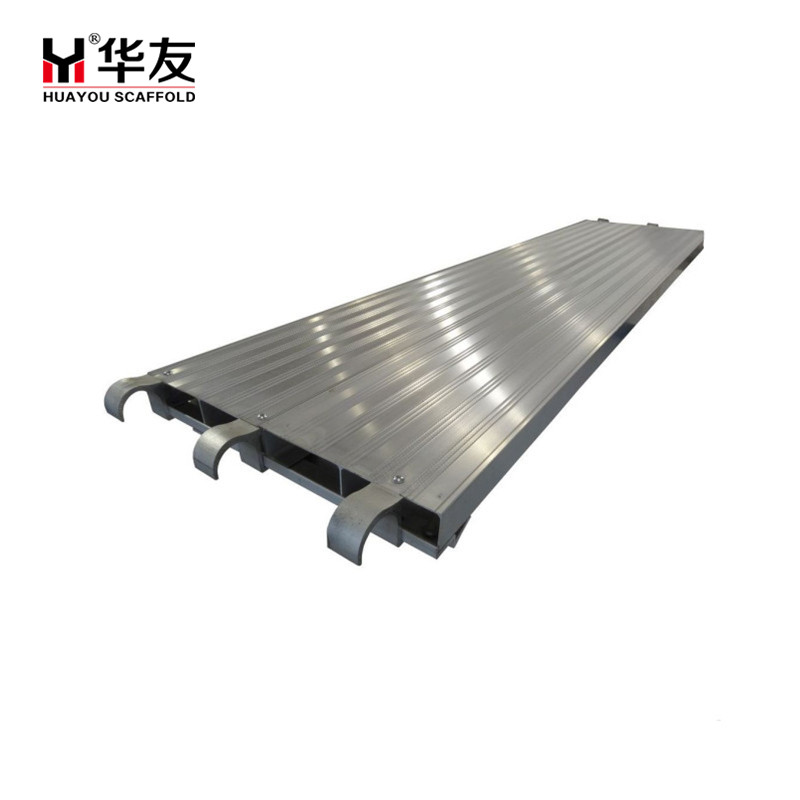

The main components for octagonlock scaffolding are standard, ledger, diagonal brace. Besides, there are some other parts such as adjustable screw jack, staircase, plank and so on.

Octagonlock scaffolding Vs. ringlock scaffolding

The biggest difference between the octagonalock scaffolding and the ringlock scaffolding is the ring welded on the standard, as the outer edge of the octagonalock system is octagon, so it will have impact on the difference as following:

Node torsion resistance

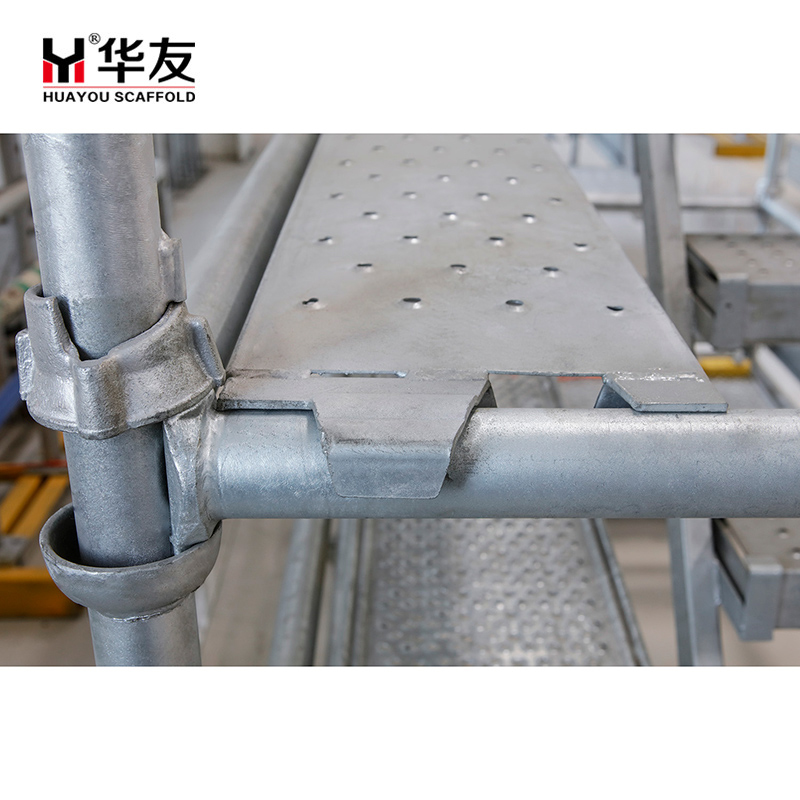

1.Octagonlock Scaffolding: when the Ledger and the standard are connected, the U-shaped groove of the octagonlock ledger is in connect with the edge of the octagon ring. The octagonal ring is the surface contact plus the pin, forming two groups of stable and reliable triangular force-bearing system with strong overall torsional stiffness. And also cause the octagon ring, the unique edger, make the ledger head will not move from one side to other side

2.Ringlock Scaffolding: the U-shaped groove of the ringlock ledger is connect with the rosette which is the point contact and due to the rosette is round edger , that maybe can have a slight movement when using in the project.

Assembling

1.Octagonlock Scaffolding: the standard welded with sleeve spigot and easy to assemble

2.Ringlock Scaffolding: The standard riveted with joint pin, maybe will be take off, and also need base collar to assemble,

Wedge pin can prevent jumping off

1.Octagonlock Scaffolding: the wedge pin is curved can prevent jumping off

2.Ringlock Scaffolding: The wedge pin is straight

Product detail pictures:

Related Product Guide:

All we do is always associated with our tenet Customer first, Trust first, devoting on the food packaging and environmental protection for Quality Inspection For Ringlock Scaffolding System - Octagonlock Scaffolding System – Huayou , The product will supply to all over the world, such as: Grenada, Guyana, Malawi, There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

This supplier stick to the principle of Quality first, Honesty as base, it is absolutely to be trust.