Professional Frame Welding Service

Product Introduction

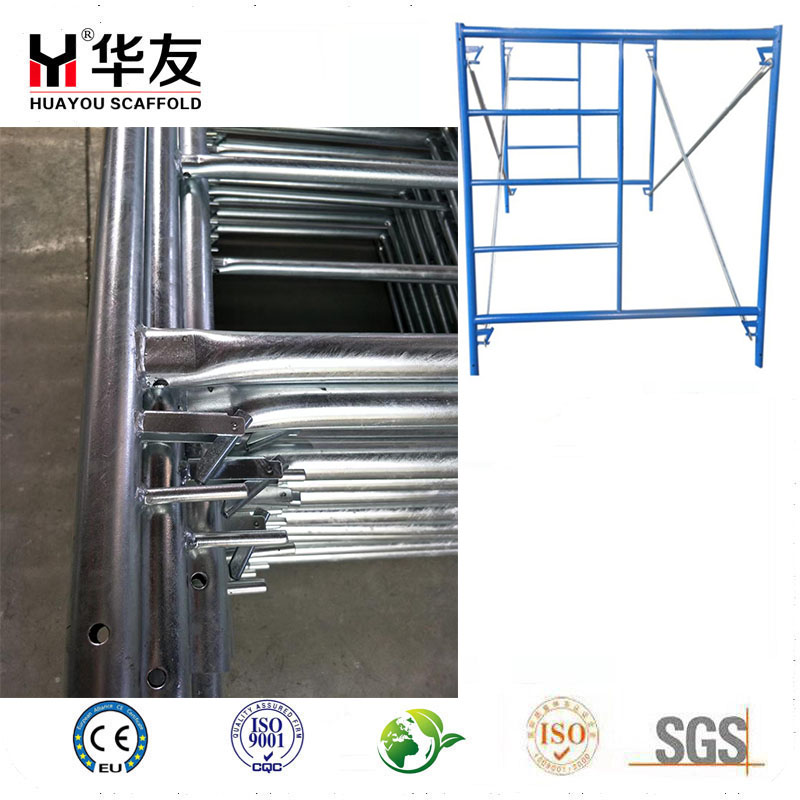

Introducing our professional frame welding service, the perfect solution for all your scaffolding needs. Designed to provide a sturdy and reliable platform for workers on a variety of projects, our frame scaffolding systems ensure safety and efficiency on construction sites. Whether you are constructing a new building, renovating an existing structure or undertaking any large-scale project, our frame scaffolding systems are the ideal choice.

Our comprehensive frame scaffolding system includes essential components such as frames, cross braces, base jacks, U-jacks, hooked planks, connecting pins, etc. Each element is carefully crafted to the highest industry standards to ensure durability and stability. With our professional frame welding service, you can be confident that every piece of scaffolding is expertly welded to provide maximum strength and support.

Scaffolding Frames

1. Scaffolding Frame Specification-South Asia Type

| Name | Size mm | Main Tube mm | Other Tube mm | steel grade | surface |

| Main Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1524 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 914x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| H Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1219 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x914 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| Horizontal/Walking Frame | 1050x1829 | 33x2.0/1.8/1.6 | 25x1.5 | Q195-Q235 | Pre-Galv. |

| Cross Brace | 1829x1219x2198 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | |

| 1829x914x2045 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1928x610x1928 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x1219x1724 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x610x1363 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. |

2. Walk Thru Frame -American Type

| Name | Tube and Thickness | Type Lock | steel grade | Weight kg | Weight Lbs |

| 6'4"H x 3'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 18.60 | 41.00 |

| 6'4"H x 42"W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 19.30 | 42.50 |

| 6'4"H X 5'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 21.35 | 47.00 |

| 6'4"H x 3'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 18.15 | 40.00 |

| 6'4"H x 42"W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 19.00 | 42.00 |

| 6'4"H X 5'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 21.00 | 46.00 |

3. Mason Frame-American Type

| Name | Tube Size | Type Lock | Steel Grade | Weight Kg | Weight Lbs |

| 3'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 12.25 | 27.00 |

| 4'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 15.00 | 33.00 |

| 5'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 16.80 | 37.00 |

| 6'4''H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 20.40 | 45.00 |

| 3'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 12.25 | 27.00 |

| 4'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 15.45 | 34.00 |

| 5'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 16.80 | 37.00 |

| 6'4''H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 19.50 | 43.00 |

4. Snap On Lock Frame-American Type

| Dia | width | Height |

| 1.625'' | 3'(914.4mm)/5'(1524mm) | 4'(1219.2mm)/20''(508mm)/40''(1016mm) |

| 1.625'' | 5' | 4'(1219.2mm)/5'(1524mm)/6'8''(2032mm)/20''(508mm)/40''(1016mm) |

5.Flip Lock Frame-American Type

| Dia | Width | Height |

| 1.625'' | 3'(914.4mm) | 5'1''(1549.4mm)/6'7''(2006.6mm) |

| 1.625'' | 5'(1524mm) | 2'1''(635mm)/3'1''(939.8mm)/4'1''(1244.6mm)/5'1''(1549.4mm) |

6. Fast Lock Frame-American Type

| Dia | Width | Height |

| 1.625'' | 3'(914.4mm) | 6'7''(2006.6mm) |

| 1.625'' | 5'(1524mm) | 3'1''(939.8mm)/4'1''(1244.6mm)/5'1''(1549.4mm)/6'7''(2006.6mm) |

| 1.625'' | 42''(1066.8mm) | 6'7''(2006.6mm) |

7. Vanguard Lock Frame-American Type

| Dia | Width | Height |

| 1.69'' | 3'(914.4mm) | 5'(1524mm)/6'4''(1930.4mm) |

| 1.69'' | 42''(1066.8mm) | 6'4''(1930.4mm) |

| 1.69'' | 5'(1524mm) | 3'(914.4mm)/4'(1219.2mm)/5'(1524mm)/6'4''(1930.4mm) |

Product Advantage

One of the main advantages of frame welding is its strength and stability. The welded frame provides a sturdy structure that can support heavy loads, making it ideal for a variety of construction projects. This durability ensures that workers have a safe platform to perform their tasks, reducing the risk of accidents. In addition, the frame scaffolding system is relatively easy to assemble and disassemble, which can save time and labor costs on site.

In addition, our company was established in 2019 with the goal of expanding into the international market and has successfully supplied frame scaffolding system to nearly 50 countries. Our complete procurement system ensures that we can meet diverse customer needs and provide high-quality products that meet safety standards.

Product Shortcoming

One significant disadvantage is that welded frames can corrode over time, especially in harsh environments. This can compromise the integrity of the scaffolding and require regular inspection and maintenance. Additionally, welded frames may be heavier than non-welded frames, which may present challenges during transportation and installation.

FAQ

Q1:What is a Scaffolding System?

The frame scaffolding system consists of several key components, including the frame, cross braces, base jacks, U-head jacks, planks with hooks, and connecting pins. Together, these elements create a stable and secure platform that supports workers and their equipment at varying heights. The design is easy to assemble and disassemble, making it ideal for both temporary and permanent structures.

Q2:Why is frame welding important?

Frame welding is critical to ensuring the integrity and strength of the scaffolding system. Proper welding techniques create strong joints that can withstand the weight and pressure of workers and materials. Following industry standards and best practices is essential to ensuring safety on the job site.

Q3:How to choose the right frame scaffolding system?

When selecting a frame scaffolding system, consider the specific requirements of your project, including height, load capacity, and the type of work being performed. Our company has been exporting scaffolding systems since 2019 and has successfully served clients in nearly 50 countries. We have developed a comprehensive procurement system to ensure that our clients receive high-quality products that meet their needs.