Polypropylene Plastic PVC construction Formwork

Company Introduction

PP Formwork Introduction:

1. Hollow Plastic Polypropylene Formwork

Normal information

| Size(mm) | Thickness(mm) | Weight kg/pc | Qty pcs/20ft | Qty pcs/40ft |

| 1220x2440 | 12 | 23 | 560 | 1200 |

| 1220x2440 | 15 | 26 | 440 | 1050 |

| 1220x2440 | 18 | 31.5 | 400 | 870 |

| 1220x2440 | 21 | 34 | 380 | 800 |

| 1250x2500 | 21 | 36 | 324 | 750 |

| 500x2000 | 21 | 11.5 | 1078 | 2365 |

| 500x2500 | 21 | 14.5 | / | 1900 |

For Plastic Formwork, the max length is 3000mm, max thickness 20mm, max width 1250mm, if you have other requirements, please let me know, we will try our best to give you support, even customized products.

2. Advantages

1) Reusable for 60-100 times

2)100% water proof

3) No release oil required

4) High workability

5) Light weight

6) Easy repaire

7) Save cost

| Character | Hollow Plastic Formwork | Modular Plastic Formwork | PVC Plastic Formwork | Plywood Formwork | Metal Formwork |

| Wear resistance | Good | Good | Bad | Bad | Bad |

| Corrosion resistance | Good | Good | Bad | Bad | Bad |

| Tenacity | Good | Bad | Bad | Bad | Bad |

| Impact strength | High | Easy broken | Normal | Bad | Bad |

| Warp after used | No | No | Yes | Yes | No |

| Recycle | Yes | Yes | Yes | No | Yes |

| Bearing Capacity | High | Bad | Normal | Normal | Hard |

| Eco-friendly | Yes | Yes | Yes | No | No |

| Cost | Lower | Higher | High | Lower | High |

| Reusable times | Over 60 | Over 60 | 20-30 | 3-6 | 100 |

3. Production and Loading:

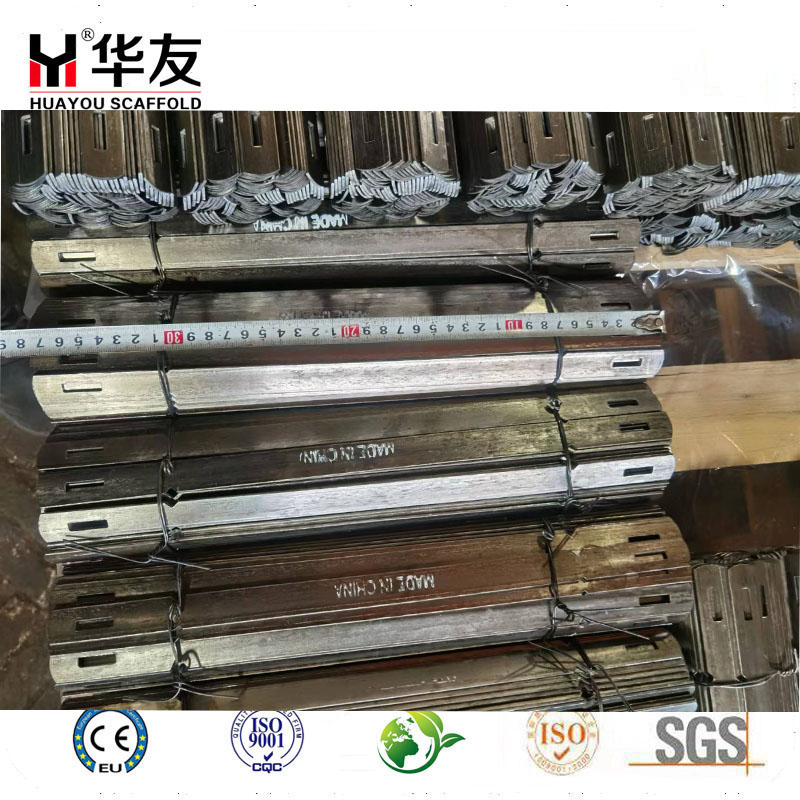

Raw materials are very important for product quality. We keep high requirements to select raw material and have a very qualified raw materials facotry.

Material is Polypropylene.

All our production procedure have a very strict management and all our workers are very professional to control quality and every details when producing. High production capacity and lower cost controlling can help us to get more competitive advantages.

With well pakcages, Pearl cotton can protect goods from impact when transportation. And we also will use wooden pallets which is easy for loading and unloading and storage. All our works are to give our customers help.

Keep goods well also need skilled loading staff. 10 Years experience can give you promise.

FAQ:

Q1: Where is the loading port?

A: Tianjin Xin port

Q2: What's the MOQ of the product?

A: Different item has different MOQ, can be negotiated.

Q3: What certificates do you have?

A: We have ISO 9001, SGS etc.

Q4: Can I get some samples?

A: Yes, Sample is free, but shipping cost is on your side.

Q5: How long is the production cycle after ordering?

A: Generally need around 20-30 days.

Q6: What is the payment methods?

A: T/T or 100% irrevocable LC at sight, can be negotiated.

Conclusion

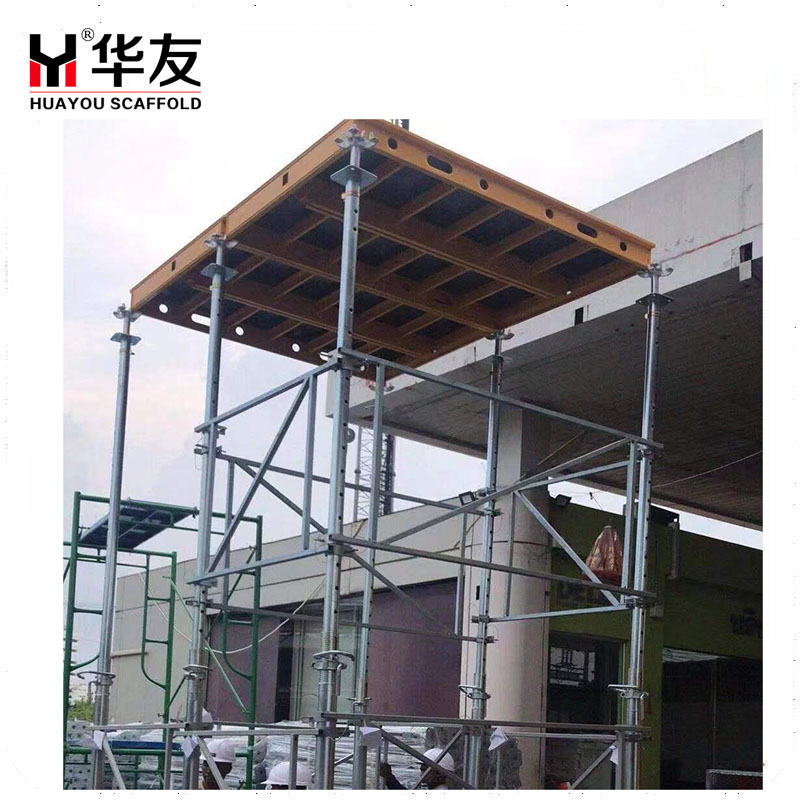

The modular design of our PVC formwork allows for quick assembly and disassembly, significantly speeding up the construction process. Each panel interlocks seamlessly, providing a secure and stable structure for pouring concrete. This efficiency not only saves time but also reduces labor costs, making it an economical choice for contractors and builders alike.

Our PVC Plastic Construction Formwork is also environmentally friendly. Made from recyclable materials, it contributes to sustainable building practices while maintaining high performance standards. The smooth surface of the formwork ensures a clean finish on your concrete structures, eliminating the need for extensive post-pour treatments.

Whether you are working on residential, commercial, or industrial projects, our PVC formwork is versatile enough to meet a variety of construction requirements. It is suitable for walls, slabs, and foundations, making it an essential tool for any construction site.

In summary, our PVC Plastic Construction Formwork combines strength, efficiency, and sustainability, making it the ideal choice for modern construction projects. Experience the future of building with our innovative formwork solution and elevate your construction game today!