Multifunctional Scaffolding Formwork Frame

Product Introduction

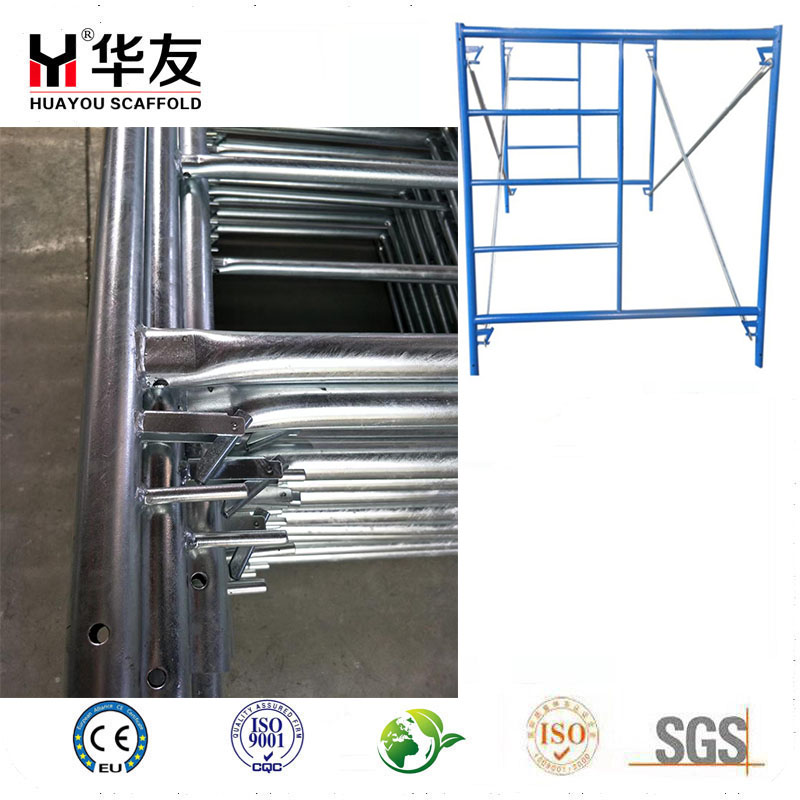

Introducing our versatile scaffolding formwork frames - the ultimate solution for your construction and renovation projects. Designed with versatility and safety in mind, our frame scaffolding systems are perfect for a variety of applications from residential construction to large commercial buildings.

Our comprehensive scaffolding system includes essential components such as frames, cross braces, base jacks, U-head jacks, hooked planks and connecting pins to ensure a sturdy and safe platform for workers. This versatile design not only improves safety, but also simplifies workflow, allowing your team to work efficiently at a variety of heights and angles.

Our versatile scaffolding formwork frame are carefully designed to meet the highest safety standards while providing the flexibility required for a wide range of projects. Whether you are constructing a new building, renovating an existing structure or carrying out maintenance work, our scaffolding systems will suit your needs.

Scaffolding Frames

1. Scaffolding Frame Specification-South Asia Type

| Name | Size mm | Main Tube mm | Other Tube mm | steel grade | surface |

| Main Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1524 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 914x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| H Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1219 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x914 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| Horizontal/Walking Frame | 1050x1829 | 33x2.0/1.8/1.6 | 25x1.5 | Q195-Q235 | Pre-Galv. |

| Cross Brace | 1829x1219x2198 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | |

| 1829x914x2045 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1928x610x1928 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x1219x1724 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x610x1363 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. |

2. Walk Thru Frame -American Type

| Name | Tube and Thickness | Type Lock | steel grade | Weight kg | Weight Lbs |

| 6'4"H x 3'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 18.60 | 41.00 |

| 6'4"H x 42"W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 19.30 | 42.50 |

| 6'4"H X 5'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 21.35 | 47.00 |

| 6'4"H x 3'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 18.15 | 40.00 |

| 6'4"H x 42"W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 19.00 | 42.00 |

| 6'4"H X 5'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 21.00 | 46.00 |

3. Mason Frame-American Type

| Name | Tube Size | Type Lock | Steel Grade | Weight Kg | Weight Lbs |

| 3'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 12.25 | 27.00 |

| 4'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 15.00 | 33.00 |

| 5'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 16.80 | 37.00 |

| 6'4''H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 20.40 | 45.00 |

| 3'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 12.25 | 27.00 |

| 4'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 15.45 | 34.00 |

| 5'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 16.80 | 37.00 |

| 6'4''H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 19.50 | 43.00 |

4. Snap On Lock Frame-American Type

| Dia | width | Height |

| 1.625'' | 3'(914.4mm)/5'(1524mm) | 4'(1219.2mm)/20''(508mm)/40''(1016mm) |

| 1.625'' | 5' | 4'(1219.2mm)/5'(1524mm)/6'8''(2032mm)/20''(508mm)/40''(1016mm) |

5.Flip Lock Frame-American Type

| Dia | Width | Height |

| 1.625'' | 3'(914.4mm) | 5'1''(1549.4mm)/6'7''(2006.6mm) |

| 1.625'' | 5'(1524mm) | 2'1''(635mm)/3'1''(939.8mm)/4'1''(1244.6mm)/5'1''(1549.4mm) |

6. Fast Lock Frame-American Type

| Dia | Width | Height |

| 1.625'' | 3'(914.4mm) | 6'7''(2006.6mm) |

| 1.625'' | 5'(1524mm) | 3'1''(939.8mm)/4'1''(1244.6mm)/5'1''(1549.4mm)/6'7''(2006.6mm) |

| 1.625'' | 42''(1066.8mm) | 6'7''(2006.6mm) |

7. Vanguard Lock Frame-American Type

| Dia | Width | Height |

| 1.69'' | 3'(914.4mm) | 5'(1524mm)/6'4''(1930.4mm) |

| 1.69'' | 42''(1066.8mm) | 6'4''(1930.4mm) |

| 1.69'' | 5'(1524mm) | 3'(914.4mm)/4'(1219.2mm)/5'(1524mm)/6'4''(1930.4mm) |

Product Advantage

1. Versatility: The frame scaffolding system is suitable for many applications from residential construction to large commercial projects. It includes basic components such as frames, cross braces, base jacks, U-jacks, wooden boards with hooks and connecting pins to suit various construction needs.

2. Easy to Assemble: The design of the frame system allows for quick and easy assembly and disassembly. This efficiency can significantly reduce labor costs and project timelines, allowing workers to focus on their tasks without unnecessary delays.

3. Enhanced Safety: The versatile scaffolding system is sturdy in construction and provides a safe working environment. Safety features such as hooked wooden planks are included to ensure workers can walk on the platform with confidence.

Product shortcoming

1. Initial Cost: While the long-term benefits are considerable, the initial investment in a versatile scaffolding system can be high. Companies must weigh this cost against their budget and project requirements.

2. Maintenance requirements: Regular maintenance is essential to ensure the safety and longevity of the scaffolding system. Ignoring this may cause structural problems and pose risks to workers.

3. Storage Space: The components of a frame scaffolding system take up considerable space when not in use. Companies must plan for adequate storage space to keep the equipment organized and in good condition.

FAQ

Q1:What is a Scaffolding System?

Frame scaffolding systems are made up of several key components, including frames, cross braces, base jacks, U-head jacks, planks with hooks, and connecting pins. Together, these elements create a safe and secure platform for workers to safely perform tasks at a variety of heights.

Q2:What are the benefits of using framework scaffolding?

Frame scaffolding systems are highly adaptable and can be used in a variety of projects. They provide excellent support and stability, which is essential to ensure worker safety. In addition, their modular design allows for quick assembly and disassembly, making them ideal for projects with tight timelines.

Q3:How to choose the right scaffolding system?

When choosing a scaffolding system, consider the specific requirements of your project, including height, load capacity, and the type of work being performed. It is also vital to ensure that the scaffolding complies with local safety regulations.

Q4:Why choose us?

Since establishing our export company in 2019, we have expanded our reach to nearly 50 countries around the world. Our commitment to quality and safety has enabled us to establish a complete procurement system to ensure our customers receive the scaffolding solution that best suits their needs.