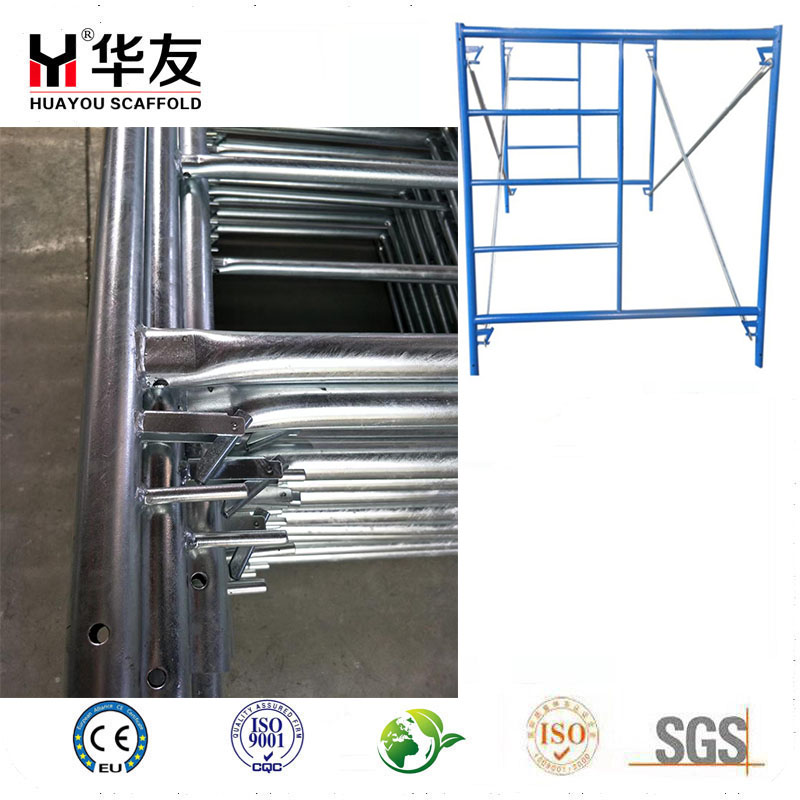

Multifunctional Frame Scaffolding Prop

Company Introduction

Since our inception in 2019, we have been committed to expanding our market coverage and providing first-class scaffolding solutions to customers around the world. With a persistent commitment to quality and customer satisfaction, our export company has successfully established a presence in nearly 50 countries. Over the years, we have developed a comprehensive procurement system that enables us to source the best materials and provide excellent products to our customers.

With our versatile frame scaffolding stanchions, you can rest assured that you are investing in a product that will not only improve safety but also increase efficiency on the job site. Whether you are a contractor, builder or DIY enthusiast, our scaffolding systems are designed to meet your needs and exceed your expectations. Choose our versatile frame scaffolding stanchions for your next project and experience the difference in quality and performance.

Scaffolding Frames

1. Scaffolding Frame Specification-South Asia Type

| Name | Size mm | Main Tube mm | Other Tube mm | steel grade | surface |

| Main Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1524 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 914x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| H Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1219 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x914 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| Horizontal/Walking Frame | 1050x1829 | 33x2.0/1.8/1.6 | 25x1.5 | Q195-Q235 | Pre-Galv. |

| Cross Brace | 1829x1219x2198 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | |

| 1829x914x2045 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1928x610x1928 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x1219x1724 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x610x1363 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. |

2. Walk Thru Frame -American Type

| Name | Tube and Thickness | Type Lock | steel grade | Weight kg | Weight Lbs |

| 6'4"H x 3'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 18.60 | 41.00 |

| 6'4"H x 42"W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 19.30 | 42.50 |

| 6'4"H X 5'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 21.35 | 47.00 |

| 6'4"H x 3'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 18.15 | 40.00 |

| 6'4"H x 42"W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 19.00 | 42.00 |

| 6'4"H X 5'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 21.00 | 46.00 |

3. Mason Frame-American Type

| Name | Tube Size | Type Lock | Steel Grade | Weight Kg | Weight Lbs |

| 3'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 12.25 | 27.00 |

| 4'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 15.00 | 33.00 |

| 5'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 16.80 | 37.00 |

| 6'4''H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 20.40 | 45.00 |

| 3'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 12.25 | 27.00 |

| 4'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 15.45 | 34.00 |

| 5'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 16.80 | 37.00 |

| 6'4''H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 19.50 | 43.00 |

4. Snap On Lock Frame-American Type

| Dia | width | Height |

| 1.625'' | 3'(914.4mm)/5'(1524mm) | 4'(1219.2mm)/20''(508mm)/40''(1016mm) |

| 1.625'' | 5' | 4'(1219.2mm)/5'(1524mm)/6'8''(2032mm)/20''(508mm)/40''(1016mm) |

5.Flip Lock Frame-American Type

| Dia | Width | Height |

| 1.625'' | 3'(914.4mm) | 5'1''(1549.4mm)/6'7''(2006.6mm) |

| 1.625'' | 5'(1524mm) | 2'1''(635mm)/3'1''(939.8mm)/4'1''(1244.6mm)/5'1''(1549.4mm) |

6. Fast Lock Frame-American Type

| Dia | Width | Height |

| 1.625'' | 3'(914.4mm) | 6'7''(2006.6mm) |

| 1.625'' | 5'(1524mm) | 3'1''(939.8mm)/4'1''(1244.6mm)/5'1''(1549.4mm)/6'7''(2006.6mm) |

| 1.625'' | 42''(1066.8mm) | 6'7''(2006.6mm) |

7. Vanguard Lock Frame-American Type

| Dia | Width | Height |

| 1.69'' | 3'(914.4mm) | 5'(1524mm)/6'4''(1930.4mm) |

| 1.69'' | 42''(1066.8mm) | 6'4''(1930.4mm) |

| 1.69'' | 5'(1524mm) | 3'(914.4mm)/4'(1219.2mm)/5'(1524mm)/6'4''(1930.4mm) |

Main feature

1. The main features of frame scaffolding systems are their sturdy design and versatility.

2. The main frame, available in a variety of types, is the backbone of the scaffolding structure, ensuring stability and support. This adaptability allows for easy assembly and disassembly, making it ideal for both temporary and long-term applications.

3. Frame scaffolding is widely used in various construction projects, from residential buildings to large commercial buildings. It provides a safe working platform for workers of different heights to facilitate tasks such as painting, plastering and bricklaying.

4. It can also be used for maintenance work, facilitating access to hard-to-reach areas without compromising safety.

Product Advantage

1. One of the most prominent benefits of multi-functional frame scaffolding stanchions is their ability to enhance safety. With a well-constructed frame system, workers can complete their tasks with confidence, knowing they are supported by a reliable and sturdy platform.

2. These scaffolding systems are easy to assemble and disassemble, which means projects can progress faster, reducing downtime and increasing productivity.

3. The frame scaffolding system is a versatile tool that can be used for a variety of projects, from residential construction to large commercial buildings.

4. The main frame is particularly adaptable and can be adapted to meet the specific needs of any construction site.

Application

1. One of the main applications of frame scaffolding is to provide construction workers with a safe working platform. Whether it is bricklaying, painting or installing fixtures, the scaffolding system allows workers to access heights safely.

2. The sturdy design of frame scaffolding ensures that it can support heavy objects, making it suitable for a variety of construction activities.

3. Since establishing our export company in 2019, our business scope has expanded to nearly 50 countries around the world. Our commitment to quality and safety allows us to establish a complete procurement system to meet the various needs of our customers. By providing versatile frame scaffolding, we ensure that our customers can get reliable and efficient solutions for their construction projects.

FAQS

Q1:What is scaffolding?

A frame scaffold is a temporary structure used to support workers and materials during construction or maintenance tasks. It is typically made up of several key components, including a frame, cross braces, base jacks, U-jacks, planks with hooks, and connecting pins. The main frame is the backbone of the system, providing stability and strength.

Q2:Why choose multifunctional frame scaffolding?

The versatility of frame scaffolding allows it to be used in a variety of applications, from residential renovations to large commercial projects. Its adaptability means it can be configured to meet the specific needs of any construction site, ensuring workers have a safe and reliable platform to carry out their tasks.

Q3:How to build a scaffolding?

Building a frame scaffold requires careful planning and adherence to safety regulations. Before assembling the frame, you must ensure that the ground is level and stable. Each component should be securely connected and should be checked regularly to maintain safety standards.

Q4:Why trust our company?

Since establishing our export company in 2019, we have expanded our reach to nearly 50 countries around the world. Our commitment to quality and safety has enabled us to establish a complete procurement system that ensures our customers receive the best products for their scaffolding needs. With our versatile frame scaffolding, you can rest assured that you are investing in a reliable solution for your construction project.