Metal Plank Is Easy To Carry And Install

Product Introduction

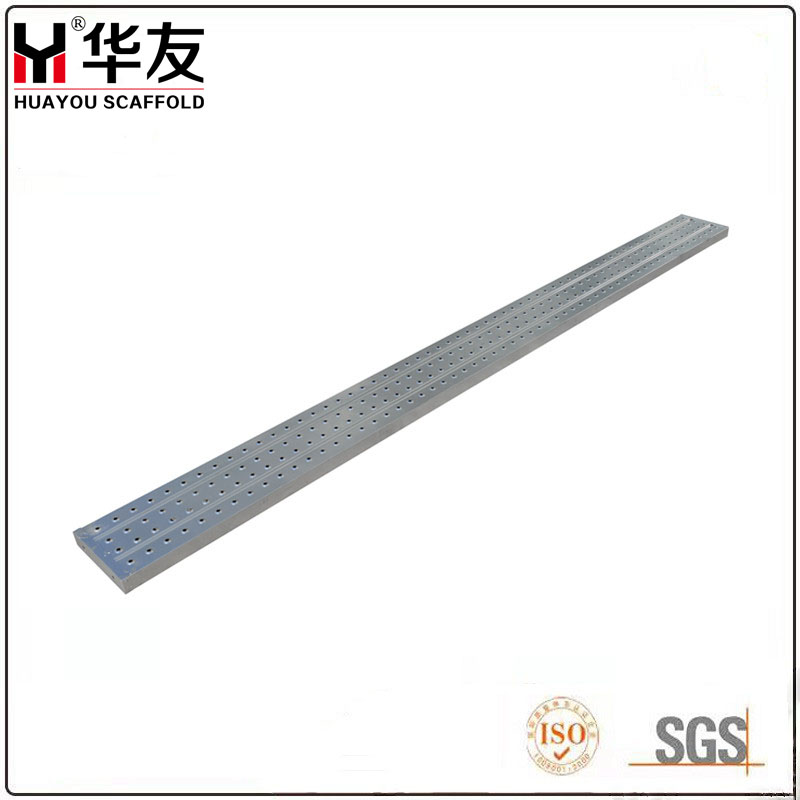

Introducing our premium steel plates, the ultimate solution to the scaffolding needs of the construction industry. Designed to provide unmatched strength and durability, our steel plates are a modern alternative to traditional wooden and bamboo scaffolding. Made from high quality steel, these plates are not only strong and durable but also lightweight, making them very easy to carry and install on any construction site.

Our steel plank, also known as steel scaffolding panels or steel building panels, are engineered to meet the rigorous demands of construction projects while ensuring safety and reliability. Our focus on innovation and quality develops products that stand the test of time, providing a stable platform for workers and materials.

Whether you are a contractor looking for a reliable scaffolding solution, or a construction manager seeking to improve site safety, our steel plates are the ideal choice. Their simple installation process allows for quick set-up, minimising downtime and maximising productivity.

Product description

Scaffolding Steel plank have many name for different markets, for example steel board, metal plank, metal board, metal deck, walk board, walk platform etc. Until now, we almost can produce all different types and size base on customers requirements.

For Australian markets: 230x63mm, thickness from 1.4mm to 2.0mm.

For Southeast Asia markets, 210x45mm, 240x45mm, 300x50mm, 300x65mm.

For Indonesia markets, 250x40mm.

For Hongkong markets, 250x50mm.

For European markets, 320x76mm.

For Middle east markets, 225x38mm.

Can be said, if you have different drawings and details, we can produce what you want according to your requirements. And professional machine, mature skill worker, large scale warehouse and factory, can give you more choice. High quality, reasonable price, best delivery. Nobody can refuse.

Size as following

|

Southeast Asia Markets |

|||||

|

Item |

Width (mm) |

Height (mm) |

Thickness (mm) |

Length (m) |

Stiffener |

|

Metal Plank |

210 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

240 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

|

250 |

50/40 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

300 |

50/65 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

The Middle east Market |

|||||

|

Steel Board |

225 |

38 |

1.5-2.0mm |

0.5-4.0m |

box |

|

Australian Market For kwikstage |

|||||

| Steel Plank | 230 | 63.5 | 1.5-2.0mm | 0.7-2.4m | Flat |

| European Markets for Layher scaffolding | |||||

| Plank | 320 | 76 | 1.5-2.0mm | 0.5-4m | Flat |

Product Advantage

1. One of the most significant advantages of steel plates is their portability. This transportation convenience not only saves time, but also reduces labor costs because fewer workers are needed to move materials.

2. Metal plank are designed to be installed quickly. Its interlocking system allows for quick assembly and disassembly, which is crucial in fast-paced construction environments. This efficiency can shorten project timelines and increase productivity, making steel plate the first choice for many contractors.

Product shortcoming

1. One significant issue is their susceptibility to corrosion, especially in harsh weather conditions. While many manufacturers offer protective coatings, these coatings wear away over time and require regular maintenance to ensure safety and longevity.

2. The initial cost of steel panels may be higher than traditional wood panels. For smaller projects or companies with tight budgets, this upfront investment can be a hindrance, despite the long-term savings in labor and increased durability.

Application

In the ever-evolving construction industry, efficiency and safety are of paramount importance. One product that has gained a lot of attention in recent years is metal sheeting, specifically steel sheeting. Designed to replace traditional wooden and bamboo boards, this innovative scaffolding solution offers a range of advantages that make it an ideal choice for construction professionals.

The installation process for the steel panels is very simple. Designed to be assembled and disassembled quickly, these panels can be installed in a fraction of the time it takes to install wooden or bamboo scaffolding. This efficiency is especially beneficial on projects with tight deadlines, allowing contractors to meet deadlines without compromising safety.

Since establishing our export company in 2019, we have expanded our reach to nearly 50 countries around the world. Our commitment to quality and customer satisfaction has enabled us to establish a comprehensive procurement system to ensure that our customers receive the best products. As the demand for reliable scaffolding solutions continues to grow, sheet metal is expected to become a must-have in construction projects around the world.

How Easy Are They To Move And Install

Compared to wooden boards, steel plates are lightweight and can be easily carried by workers. Their design ensures they can be quickly assembled and disassembled, saving valuable time on the construction site. This ease of use is a significant advantage, especially for projects that require frequent relocation of scaffolding.