High Quality Steel Formwork Efficient Construction

Product Introduction

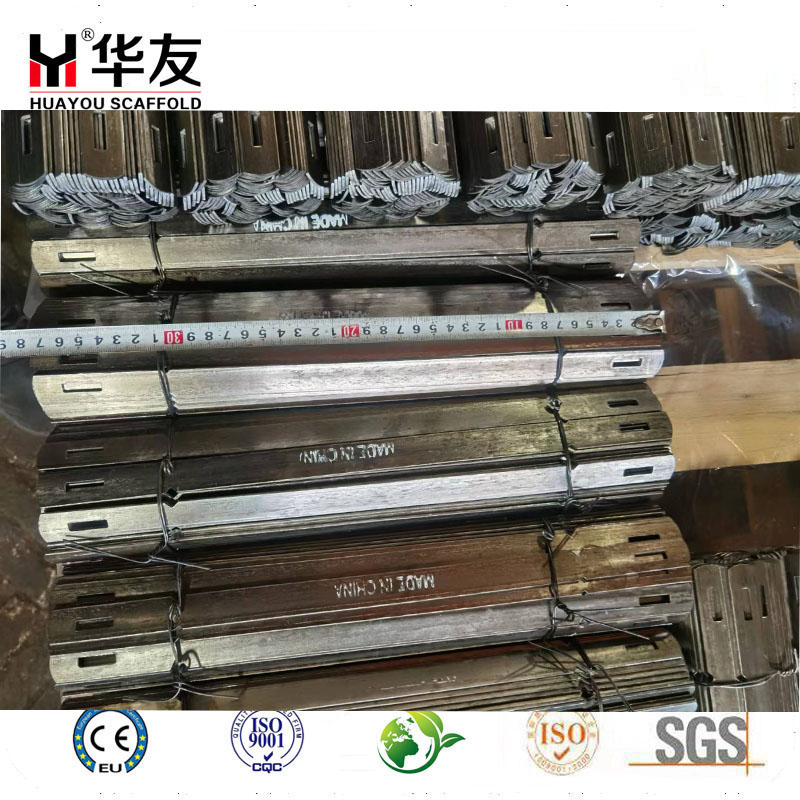

Introducing our high-quality steel formwork, the ultimate solution for efficient construction projects. Made from durable steel frames and sturdy plywood, our formwork is designed to meet the rigorous demands of modern construction. Each steel frame is carefully designed with a variety of components including F-beams, L-beams and triangles to ensure maximum stability and support to meet your construction needs.

Our steel formwork is available in a variety of standard sizes including 600x1200mm, 500x1200mm, 400x1200mm, 300x1200mm, 200x1200mm, as well as larger sizes such as 600x1500mm, 500x1500mm, 400x1500mm, 300x1500mm and 200x1500mm. This variety provides flexibility and adaptability for any construction project, whether residential, commercial or industrial.

With our high-quality steel formwork, you can expect not only superior performance, but also increased efficiency in the construction process. Our commitment to excellence and customer satisfaction is what sets us apart in the industry. Choose our steel formwork for your next project and experience the difference that quality and efficiency can make. Join the growing number of satisfied customers who trust us to meet their construction needs and let us help you build a better future.

Steel Formwork Components

|

Name |

Width (mm) |

Length (mm) |

|||

|

Steel Frame |

600 |

550 |

1200 |

1500 |

1800 |

|

500 |

450 |

1200 |

1500 |

1800 |

|

|

400 |

350 |

1200 |

1500 |

1800 |

|

|

300 |

250 |

1200 |

1500 |

1800 |

|

|

200 |

150 |

1200 |

1500 |

1800 |

|

|

Name |

Size (mm) |

Length (mm) |

|||

|

In Corner Panel |

100x100 |

900 |

1200 |

1500 |

|

|

Name |

Size(mm) |

Length (mm) |

|||

|

Outer Corner Angle |

63.5x63.5x6 |

900 |

1200 |

1500 |

1800 |

Formwork Accessories

| Name | Pic. | Size mm | Unit weight kg | Surface Treatment |

| Tie Rod | |

15/17mm | 1.5kg/m | Black/Galv. |

| Wing nut | |

15/17mm | 0.4 | Electro-Galv. |

| Round nut | |

15/17mm | 0.45 | Electro-Galv. |

| Round nut | |

D16 | 0.5 | Electro-Galv. |

| Hex nut | |

15/17mm | 0.19 | Black |

| Tie nut- Swivel Combination Plate nut | |

15/17mm | Electro-Galv. | |

| Washer | |

100x100mm | Electro-Galv. | |

| Formwork clamp-Wedge Lock Clamp | |

2.85 | Electro-Galv. | |

| Formwork clamp-Universal Lock Clamp | |

120mm | 4.3 | Electro-Galv. |

| Formwork Spring clamp | |

105x69mm | 0.31 | Electro-Galv./Painted |

| Flat Tie | |

18.5mmx150L | Self-finished | |

| Flat Tie | |

18.5mmx200L | Self-finished | |

| Flat Tie | |

18.5mmx300L | Self-finished | |

| Flat Tie | |

18.5mmx600L | Self-finished | |

| Wedge Pin | |

79mm | 0.28 | Black |

| Hook Small/Big | |

Painted silver |

Company Advantage

Since our founding in 2019, we have made significant progress in expanding our market coverage. Our export company has successfully served clients in nearly 50 countries around the world, building a reputation for quality and reliability. Over the years, we have developed a comprehensive sourcing system that ensures our clients receive the best products and services tailored to their specific needs.

Product advantage

One of the main advantages of steel formwork is its durability. The steel frame includes various components such as F-beam, L-beam and triangle steel to provide excellent strength and stability. This makes it ideal for larger projects where structural integrity is critical. Additionally, standard sizes (from 200x1200mm to 600x1500mm) allow for versatility in design and application.

Another significant advantage of steel formwork is that it is reusable. Unlike traditional wooden formwork, which may only be used a few times before deteriorating, high-quality steel formwork can be reused many times without compromising its structural integrity. Not only does this reduce material costs, but it also minimizes waste, making it a more environmentally friendly choice.

Product Shortcoming

Although high-quality steel formwork has many advantages, it also has some disadvantages. One of the issues worth noting is the initial cost. The upfront investment in steel formwork can be higher than traditional materials, which can be prohibitive for some contractors, especially for smaller projects. Additionally, the weight of steel formwork makes it more difficult to handle and transport, requiring specialized equipment and skilled labor.

Application

In the ever-evolving world of construction, the need for reliable, efficient materials is paramount. One such material that has gained popularity is high-quality steel formwork. This innovative solution is not only durable but also versatile, making it an ideal choice for a wide range of construction applications.

Steel formwork is constructed using a sturdy steel euro formwork and plywood to ensure a strong and stable structure. The steel frame consists of several components including F-shaped steel, L-shaped steel and triangular steel, which contribute to its overall strength and adaptability. These formworks are available in standard sizes such as 600x1200mm, 500x1200mm and 400x1200mm, as well as larger sizes such as 600x1500mm and 500x1500mm to meet various project needs.

The applications for high-quality steel formwork are numerous. It is commonly used to construct walls, slabs and columns, providing a reliable framework that can withstand the rigors of concrete pouring. It can be reused multiple times, which not only reduces waste but also reduces overall project costs, making it an affordable option for contractors.

FAQ

Q1:What is Steel Formwork?

Steel formwork is a building system that is a combination of steel frame and plywood. This combination ensures a strong structure capable of withstanding the stress of concrete pouring. Steel frames are made up of various components, including F-shaped bars, L-shaped bars, and triangular bars, which help to increase their strength and stability.

Q2:What sizes are available?

Steel formwork comes in a variety of standard sizes to meet different construction needs. Common sizes include 600x1200mm, 500x1200mm, 400x1200mm, 300x1200mm, 200x1200mm, as well as larger sizes such as 600x1500mm, 500x1500mm, 400x1500mm, 300x1500mm and 200x1500mm. This diversity provides flexibility in design and application.

Q3:Why choose high quality steel formwork?

Choosing high-quality steel formwork ensures that your construction project is built on a solid foundation. The durability of steel means it can be reused multiple times, reducing waste and costs. Additionally, the precision of the steel formwork results in a better finished final structure with fewer defects.