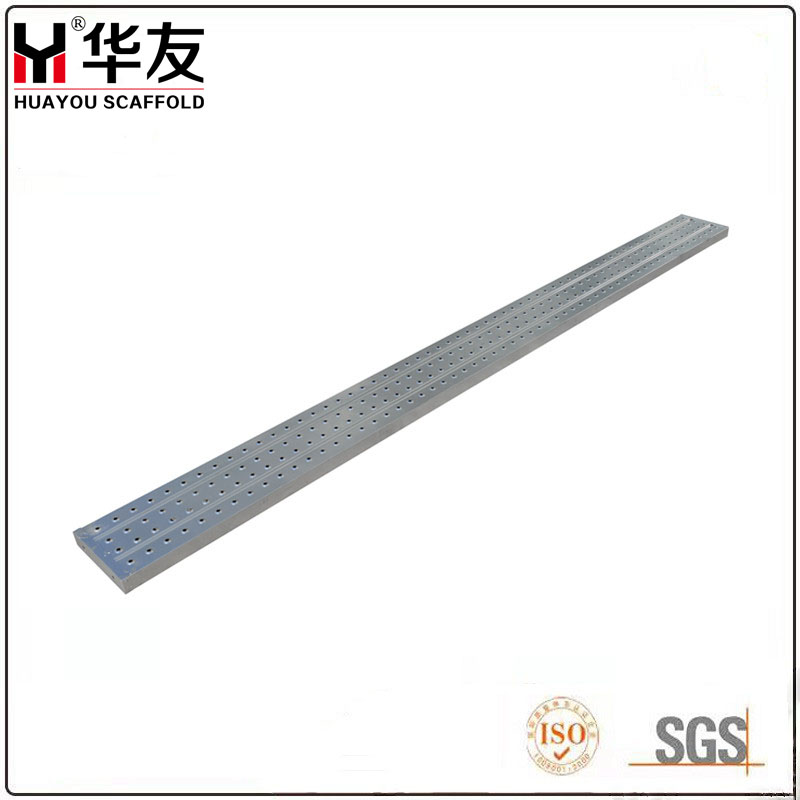

High Quality Perforated Plate Safe And Stylish

Product Introduction

Introducing our high-quality perforated panels that are the perfect blend of safety and style for your architectural and design needs. At our company, we take pride in providing products that not only meet but exceed industry standards. Our perforated panels are carefully crafted from raw materials that undergo a rigorous quality control (QC) process. We ensure that every batch is thoroughly inspected, not only for cost, but also for quality and performance.

We have 3,000 tons of raw material inventory per month to meet the needs of different customers. Our panels have successfully passed rigorous testing, including EN1004, SS280, AS/NZS 1577 and EN12811 quality standards, ensuring that the products you receive are safe and reliable.

Our high-quality perforated metal planks are more than just a product; they are a functional and aesthetically pleasing solution. Whether you are looking to improve safety in your building project or add a stylish touch to your design, our perforated panels are the ideal choice. Trust us to provide you with the quality and service you deserve as we continue to innovate and expand in markets around the world. Choose our perforated panels for a safe, stylish, high-quality solution that will stand the test of time.

Product description

Scaffolding Steel plank have many name for different markets, for example steel board, metal plank, metal board, metal deck, walk board, walk platform etc. Until now, we almost can produce all different types and size base on customers requirements.

For Australian markets: 230x63mm, thickness from 1.4mm to 2.0mm.

For Southeast Asia markets, 210x45mm, 240x45mm, 300x50mm, 300x65mm.

For Indonesia markets, 250x40mm.

For Hongkong markets, 250x50mm.

For European markets, 320x76mm.

For Middle east markets, 225x38mm.

Can be said, if you have different drawings and details, we can produce what you want according to your requirements. And professional machine, mature skill worker, large scale warehouse and factory, can give you more choice. High quality, reasonable price, best delivery. Nobody can refuse.

Company Advantage

Since establishing our export company in 2019, we have expanded our reach to nearly 50 countries around the world. This growth is a testament to our commitment to quality and customer satisfaction. Over the years, we have developed a comprehensive procurement system that enables us to source the best materials and deliver them to our customers efficiently.

Size as following

|

Southeast Asia Markets |

|||||

|

Item |

Width (mm) |

Height (mm) |

Thickness (mm) |

Length (m) |

Stiffener |

|

Metal Plank |

210 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

240 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

|

250 |

50/40 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

300 |

50/65 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

The Middle east Market |

|||||

|

Steel Board |

225 |

38 |

1.5-2.0mm |

0.5-4.0m |

box |

|

Australian Market For kwikstage |

|||||

| Steel Plank | 230 | 63.5 | 1.5-2.0mm | 0.7-2.4m | Flat |

| European Markets for Layher scaffolding | |||||

| Plank | 320 | 76 | 1.5-2.0mm | 0.5-4m | Flat |

Product Advantage

One of the main advantages of high-quality perforated panels is their ability to combine functionality with visual appeal. Perforations allow for ventilation and light transmission, making them ideal for architectural designs that require both security and style.

In addition, our perforated panels are made from raw materials that are strictly controlled by our quality control (QC) team. This ensures that each product meets strict quality standards, including EN1004, SS280, AS/NZS 1577 and EN12811. Since our export company was established in 2019, we have 3,000 tons of raw materials in stock per month, able to meet the needs of customers in nearly 50 countries.

Product Shortcoming

However, the disadvantages of premium perforated panels must be considered. While they are designed to be strong, the perforations can sometimes compromise structural integrity, especially in high-stress applications. Additionally, the aesthetics may not suit every design preference, limiting their use in certain projects.

Application

Our perforated panels are made from top quality raw materials, all of which are strictly controlled by our quality control (QC) team. We not only focus on cost, but also prioritize quality to ensure that our products meet the highest standards. We reserve 3,000 tons of raw materials every month, allowing us to efficiently meet the needs of different customers.

What sets our perforated metal plank apart is that they meet stringent quality standards. They have successfully passed EN1004, SS280, AS/NZS 1577 and EN12811 testing, ensuring they are not only stylish but also safe for a wide range of applications. From architectural design to industrial use, our panels have the durability and reliability our customers expect.

FAQS

Q1. What is perforated sheet used for?

Perforated panels are versatile and can be used in a variety of applications, including architectural design, industrial settings, and even home decoration.

Q2. How do you ensure the quality of your products?

We have a sound procurement system and our quality control team conducts comprehensive inspections to ensure that every batch of products meets the highest standards.

Q3. Can your perforated panels be customized?

Yes! We offer custom options to meet specific design and functional requirements.

Q4. What is the lead time for an order?

Our efficient supply chain enables us to fulfill orders promptly, typically within a few weeks, depending on the size and level of customization of the order.