High Quality H Timber Beam For Construction Projects

Product Introduction

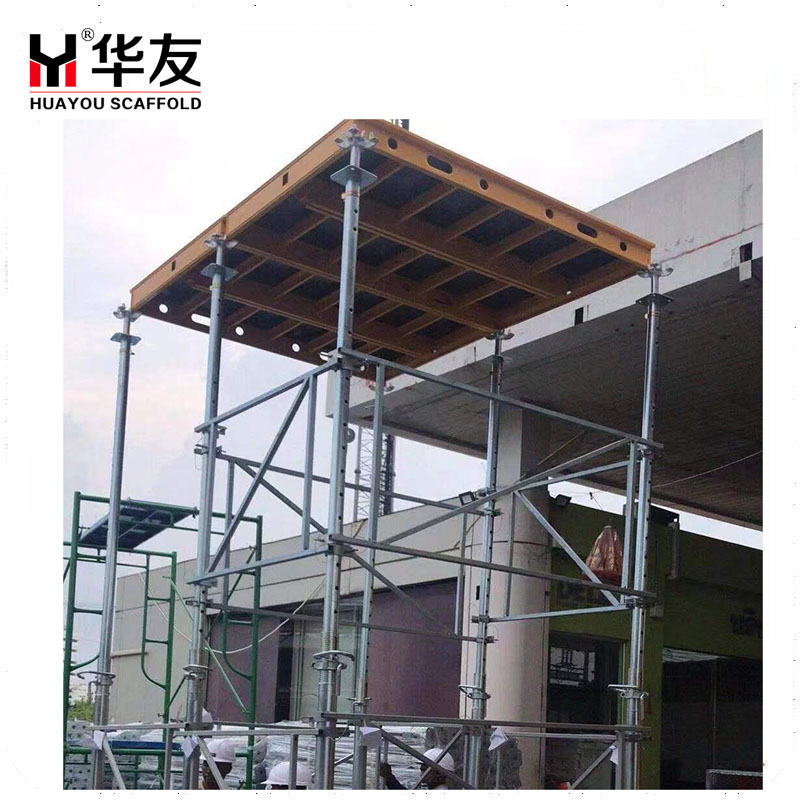

Our wooden H20 beams, also known as I beams or H beams, are designed for construction applications where weight and cost efficiency are critical.

Traditionally, steel H-beams have been favored for their high load-bearing capacity, but our wood H-beams offer a practical alternative for projects that require less weight without compromising strength. Made from premium wood, our beams are designed to provide the durability and reliability you expect from a building material while also being cost-effective. This makes them ideal for a variety of applications, from residential construction to light commercial projects.

When you choose our high-quality H timber beam, you're not just investing in a product; you're working with a company that values architectural excellence and innovation. Our beams are rigorously tested and meet industry standards, ensuring you receive a product that is both safe and effective for your building project.

Company Advantage

Since our inception in 2019, we have been working towards expanding our presence in the global market. Due to our commitment to quality and customer satisfaction, our export company has successfully served clients in nearly 50 countries. Over the years, we have developed a comprehensive sourcing system that ensures that we source only the best materials for our products.

H Beam Information

|

Name |

Size |

Materials |

Length( m) |

Middle Bridge |

|

H Timber Beam |

H20x80mm |

Poplar/Pine |

0-8m |

27mm/30mm |

|

H16x80mm |

Poplar/Pine |

0-8m |

27mm/30mm |

|

|

H12x80mm |

Poplar/Pine |

0-8m |

27mm/30mm |

H Beam/I Beam Features

1. I-beam is an important component of the internationally used building formwork system. It has the characteristics of light weight, high strength, good linearity, not easy to deform, surface resistance to water and acid and alkali, etc. It can be used all year round, with low cost amortization expenses; it can be used with professional formwork system products at home and abroad.

2. It can be widely used in various formwork systems such as horizontal formwork system, vertical formwork system (wall formwork, column formwork, hydraulic climbing formwork, etc.), variable arc formwork system and special formwork.

3. The wooden I-beam straight wall formwork is a loading and unloading formwork, which is easy to assemble. It can be assembled into formworks of various sizes within a certain range and degree, and is flexible in application. The formwork has high rigidity, and it is very convenient to connect the length and height. The formwork can be poured at a maximum of more than ten meters at a time. Because the formwork material used is light in weight, the whole formwork is much lighter than the steel formwork when assembled.

4. The system product components are highly standardized, have good reusability, and meet environmental protection requirements.

Formwork Accessories

| Name | Pic. | Size mm | Unit weight kg | Surface Treatment |

| Tie Rod | |

15/17mm | 1.5kg/m | Black/Galv. |

| Wing nut | |

15/17mm | 0.4 | Electro-Galv. |

| Round nut | |

15/17mm | 0.45 | Electro-Galv. |

| Round nut | |

D16 | 0.5 | Electro-Galv. |

| Hex nut | |

15/17mm | 0.19 | Black |

| Tie nut- Swivel Combination Plate nut | |

15/17mm | Electro-Galv. | |

| Washer | |

100x100mm | Electro-Galv. | |

| Formwork clamp-Wedge Lock Clamp | |

2.85 | Electro-Galv. | |

| Formwork clamp-Universal Lock Clamp | |

120mm | 4.3 | Electro-Galv. |

| Formwork Spring clamp | |

105x69mm | 0.31 | Electro-Galv./Painted |

| Flat Tie | |

18.5mmx150L | Self-finished | |

| Flat Tie | |

18.5mmx200L | Self-finished | |

| Flat Tie | |

18.5mmx300L | Self-finished | |

| Flat Tie | |

18.5mmx600L | Self-finished | |

| Wedge Pin | |

79mm | 0.28 | Black |

| Hook Small/Big | |

Painted silver |

Product advantage

One of the main advantages of high-quality H-beams is their low weight. Unlike traditional steel beams, wooden H-beams are easier to handle and install, significantly reducing labor costs on construction sites. Additionally, these beams are made from sustainable materials, making them an eco-friendly choice for builders looking to minimize their carbon footprint.

Another benefit is cost-effectiveness. For projects that do not require the high load-bearing capacity of steel beams, wooden H-beams offer a more economical solution without compromising on quality. This makes them an attractive choice for residential and light commercial construction.

Product Shortcoming

However, there are some disadvantages to consider. While wood H beam are suitable for light-duty applications, they may not be suitable for heavy-duty projects that require maximum strength. In this case, steel beams must be used to ensure safety and comply with building codes.

Additionally, wooden beams are susceptible to environmental factors such as moisture and pests, which can affect their lifespan. Proper handling and maintenance are essential to reducing these risks.

FAQ

Q1. What are the advantages of using wooden H20 beams?

Wooden H20 beams are lightweight, economical and environmentally friendly. They are easy to handle and install, making them a practical choice for a variety of construction projects.

Q2. Are wooden H beams as strong as steel beams?

While wooden H-beams may not match the heavy-load capacity of steel beams, they can be carefully designed to provide adequate support for light-load applications, making them suitable for many construction needs.

Q3. How do I choose the right size H beam for my project?

The size of the beam required depends on the specific load requirements of the project. Consulting a structural engineer can help determine the appropriate size.