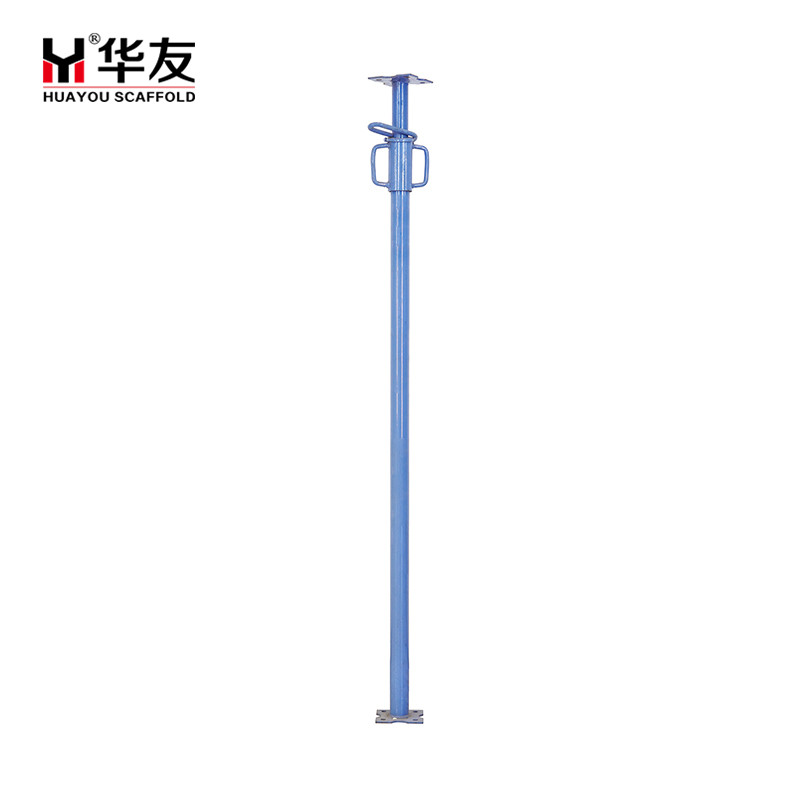

Factory Customized Scaffolding Props Formwork System - Aluminum Ringlock Scaffolding – Huayou

Factory Customized Scaffolding Props Formwork System - Aluminum Ringlock Scaffolding – Huayou Detail:

Description

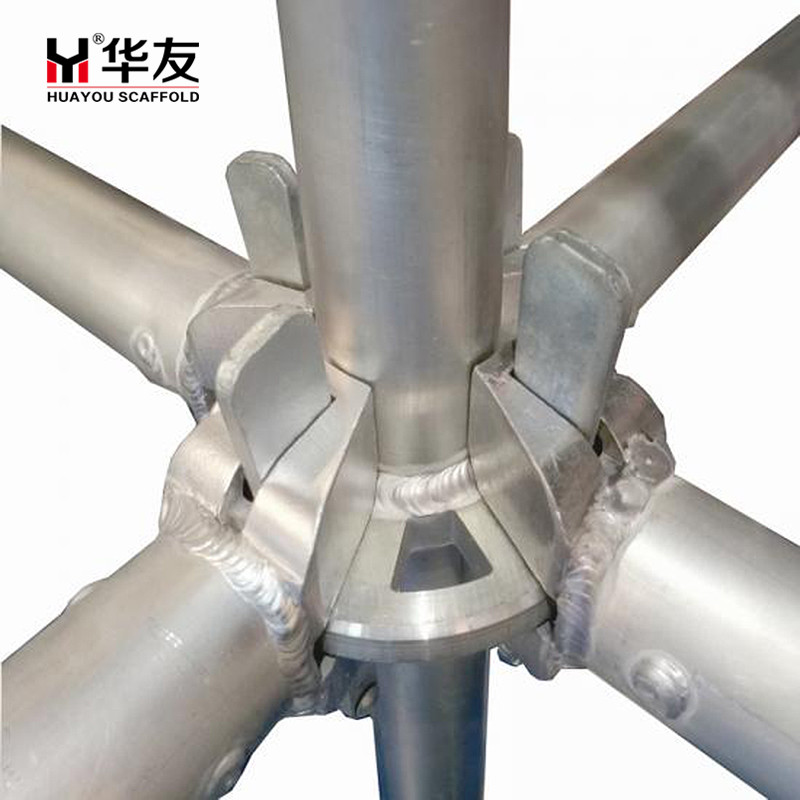

Aluninum Ringlock system is samilar as metal ringlocks, but the materials are aluminum alloy. It has better quality and will be more durable.

Aluminum Ringlock Scaffolding are all made of aluminum alloy (T6-6061), which is 1.5—2 times stronger than the traditional carbon steel pipe of scaffolding. Compare with other scaffolding system, the overall stability, strength and bearing capacity is 50% higher than that of “scaffolding pipe and coupler system ” and 20% higher than that of “cuplock system scaffolding”. ” by 20%. At the same time, ringlock scaffolding adopts special structural design to further – enhance the load-bearing capacity.

The characteristics of aluminum ringlock scaffolding

(1) Multifunctionality. According to the project and site construction needs, ringlock scaffolding can be composed of different sizes and shapes of large double-row outerior scaffodling, support scaffolding, pillar support system and other construction platforms and construction auxiliary equipment.

2) High efficiency. Simple construction, disassembly and assembly is convenient and fast, completely avoiding the bolt work and scattered fasteners loss, head assembly speed is more than 5 times faster than ordinary scaffolding, assembling and disassembling using less manpower, one person and one hammer can work, simple and efficient.

3)High safety. Due to the aluminum alloy materials, the quality is higher than other steel scaffolding, from the bending resistance, anti-shear, torsional force resistance. Structural stability, material bearing capacity hit, better bearing capacity and safety than ordinary steel scaffolding, and can be disassembled in advance of turnover, saving time and effort, is the ideal choice for the current construction safety construction.

Company advantages

Our workers are experienced and qualified to the request of welding and strict quality control department can assure you the superior quality scaffolding products.

Our sales team is professional, capable, reliable for our every customer, thery are excellent and worked in scaffolding fields for more than 8years.

Product detail pictures:

Related Product Guide:

Our growth depends to the superior products ,great talents and repeatedly strengthened technology forces for Factory Customized Scaffolding Props Formwork System - Aluminum Ringlock Scaffolding – Huayou , The product will supply to all over the world, such as: Rio de Janeiro, Lithuania, Chicago, Our company is continuing to serve customers with high quality, competitive price and timely delivery. We sincerely welcome friends from all over the world to cooperate with us and enlarge our business. If you are interested in our products, please feel free to contact us. We would love to provide you with further information.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!