Customizable Industrial Perforated Metal Planks

Size as following

|

Southeast Asia Markets |

|||||

|

Item |

Width (mm) |

Height (mm) |

Thickness (mm) |

Length (m) |

Stiffener |

|

Metal Plank |

210 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

240 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

|

250 |

50/40 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

300 |

50/65 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

The Middle east Market |

|||||

|

Steel Board |

225 |

38 |

1.5-2.0mm |

0.5-4.0m |

box |

|

Australian Market For kwikstage |

|||||

| Steel Plank | 230 | 63.5 | 1.5-2.0mm | 0.7-2.4m | Flat |

| European Markets for Layher scaffolding | |||||

| Plank | 320 | 76 | 1.5-2.0mm | 0.5-4m | Flat |

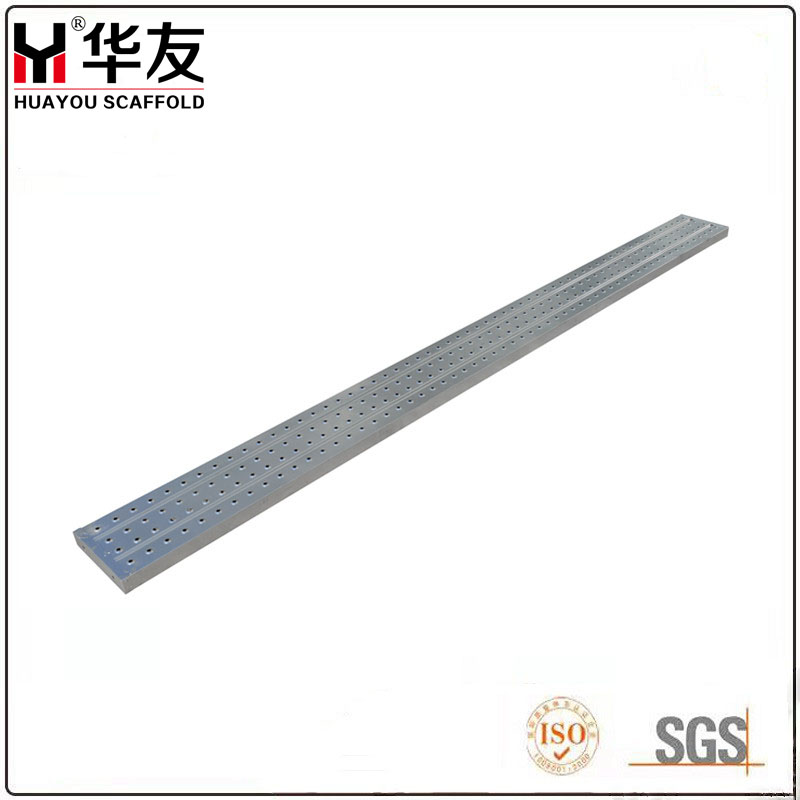

Product Introduction

Introducing our Customizable Industrial Perforated Metal Planks – the ultimate solution for your scaffolding needs in the construction industry. As a modern evolution of traditional scaffolding materials like wooden and bamboo planks, our steel planks are engineered for durability, safety, and versatility. Crafted from high-quality steel, these planks provide a robust platform that can withstand the rigors of any construction site, ensuring that your projects run smoothly and efficiently.

Our customizable industrial perforated metal planks are designed to meet the specific requirements of your project. With a variety of sizes, thicknesses, and perforation patterns available, you can tailor these planks to fit your unique scaffolding needs. The perforated design not only enhances the structural integrity of the planks but also allows for better drainage and reduces the risk of slipping, making them an ideal choice for both indoor and outdoor applications.

Main Market

1. One of the main advantages of customizable industrial perforated metal panels is their durability. Made from high-quality steel, these panels can withstand heavy loads and harsh environmental conditions, making them ideal for a variety of construction projects.

2. The perforated design allows for better drainage and reduces the risk of slips, thereby improving the safety of workers on site.

3. Customization is another important advantage. The company can customize the size, shape, and perforation pattern of the planks to meet specific project requirements. This flexibility not only improves functionality, but also allows for more efficient use of materials, ultimately saving costs.

Product Advantage

1. One of the main advantages of customizable industrial perforated metal panels is their durability. Made from high-quality steel, these panels can withstand heavy loads and harsh environmental conditions, making them ideal for a variety of construction projects.

2. The perforated design allows for better drainage and reduces the risk of slips, thereby improving the safety of workers on site.

3. Customization is another important advantage. The company can customize the size, shape, and perforation pattern of the planks to meet specific project requirements. This flexibility not only improves functionality, but also allows for more efficient use of materials, ultimately saving costs.

Product shortcoming

1. The initial investment can be higher compared to traditional wood or bamboo panels. While the long-term benefits generally outweigh the costs, budget constraints can pose a challenge for certain projects.

2. The weight of the steel plank is also a disadvantage in terms of transportation and handling. Workers may need additional equipment to move and install these steel plates, which may slow down the construction progress.

FAQ

Q1:What is Customizable Industrial Perforated Metal?

Customizable industrial perforated metal panels are steel panels designed with holes or perforations that enhance their performance. These panels can be customized to specific project requirements, including size, thickness, and hole pattern, making them ideal for a variety of applications in the construction industry.

Q2:Why choose steel plate instead of traditional materials?

Steel sheets offer greater strength and longevity than wood or bamboo. They are able to withstand weather conditions, pests and rot, ensuring a safer and more reliable scaffolding solution. Additionally, the customizable nature of perforated metal sheets can improve drainage and reduce weight, making them easier to handle on site.

Q3:How does your company support international clients?

Since we established our export company in 2019, we have successfully expanded our business scope to nearly 50 countries around the world. Our comprehensive procurement system ensures that we can meet the diverse needs of our customers and provide high-quality customizable industrial perforated metal sheets that meet international standards.

Q4:What are the benefits of using perforated metal?

The perforations in these steel plates not only reduce weight, but also improve safety by providing better traction and water drainage. This makes them an excellent choice for a variety of construction environments, ensuring workers can work safely and efficiently.